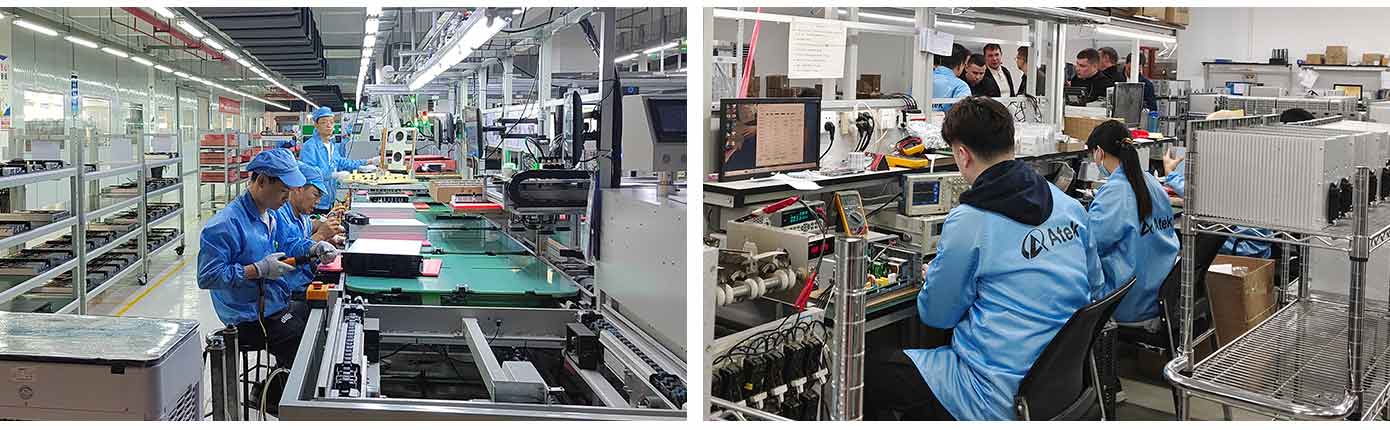

1. §°§Ò§à§â§å§Õ§à§Ó§Ñ§ß§Ú§Ö §Õ§Ý§ñ SMT §á§Ñ§Û§Ü§Ú §Ú §Ý§å§Ø§Ö§ß§Ú§ñ, §Ó§à§Ý§ß§à§Ó§Ñ§ñ §á§Ñ§Û§Ü§Ñ, §å§ã§ä§â§à§Û§ã§ä§Ó§à §Õ§Ý§ñ §Ñ§Ó§ä§à§Þ§Ñ§ä§Ú§é§Ö§ã§Ü§à§Ô§à §à§á§ä§Ú§é§Ö§ã§Ü§à§Ô§à §Ü§à§ß§ä§â§à§Ý§ñ AOI, §ä§â§Ö§ç§ã§Ý§à§Û§ß§à§Ö §â§Ñ§ã§á§í§Ý§Ú§ä§Ö§Ý§î§ß§à§Ö §å§ã§ä§â§à§Û§ã§ä§Ó§à, §å§ã§ä§â§à§Û§ã§ä§Ó§à §Õ§Ý§ñ §Ù§Ñ§á§à§Ý§ß§Ö§ß§Ú§ñ §Ô§Ö§Ý§Ö§Þ §Ú §Õ§â. §ã §Ô§à§Õ§à§Ó§à§Û §á§â§à§Ú§Ù§Ó§à§Õ§ã§ä§Ó§Ö§ß§ß§à§Û §Þ§à§ë§ß§à§ã§ä§î§ð 250 000 §Ü§à§Þ§á§Ý§Ö§Ü§ä§à§Ó.

2. §¯§Ñ§è§Ö§Ý§Ú§Ó§Ñ§ß§Ú§Ö (§ä§Ñ§â§Ô§Ö§ä§Ú§â§à§Ó§Ñ§ß§Ú§Ö) §ß§Ñ «§ß§å§Ý§Ö§Ó§à§Û §Õ§Ö§æ§Ö§Ü§ä»:

- §ã§ä§â§à§Ô§à§Ö §ã§à§Ò§Ý§ð§Õ§Ö§ß§Ú§Ö §ã§ä§Ñ§ß§Õ§Ñ§â§ä§à§Ó ISO9001 §Ú ISO14001.

3. §µ§á§â§Ñ§Ó§Ý§Ö§ß§Ú§Ö §Ú §ã§ä§Ñ§ß§Õ§Ñ§â§ä§Ú§Ù§Ñ§è§Ú§ñ:

- §ã§ä§â§à§Ô§à§Ö §ã§à§Ò§Ý§ð§Õ§Ö§ß§Ú§Ö §ã§ä§Ñ§ß§Õ§Ñ§â§ä§Ñ §á§à§Õ§Ô§à§ä§à§Ó§Ü§Ú §â§Ñ§Ò§à§é§Ö§Ô§à §Þ§Ö§ã§ä§Ñ §Õ§Ý§ñ §Ó§í§á§à§Ý§ß§Ö§ß§Ú§ñ §á§â§à§Ú§Ù§Ó§à§Õ§ã§ä§Ó§Ö§ß§ß§à§Ô§à §Ù§Ñ§Õ§Ñ§ß§Ú§ñ (6S), §å§á§â§Ñ§Ó§Ý§Ö§ß§Ú§Ö §Ú §Ü§à§ß§ä§â§à§Ý§î §Ù§Ñ §á§â§à§è§Ö§ã§ã§Ñ§Þ§Ú, §Ô§Ñ§â§Ñ§ß§ä§Ú§ñ §ã§Ó§à§Ö§Ó§â§Ö§Þ§Ö§ß§ß§à§Û §Õ§à§ã§ä§Ñ§Ó§Ü§Ú §Ú §Ò§í§ã§ä§â§à§Ö §â§Ö§Ñ§Ô§Ú§â§à§Ó§Ñ§ß§Ú§Ö §ß§Ñ §ä§â§Ö§Ò§à§Ó§Ñ§ß§Ú§ñ §Ü§Ý§Ú§Ö§ß§ä§à§Ó.

4. §¢§Ö§â§Ö§Ø§Ý§Ú§Ó§à§Ö §á§â§à§Ú§Ù§Ó§à§Õ§ã§ä§Ó§à §Ú §Ú§ß§æ§à§â§Þ§Ñ§ä§Ú§Ù§Ñ§è§Ú§ñ:

- §à§Ò§ì§Ö§Õ§Ú§ß§Ö§ß§Ú§Ö §Ò§Ö§â§Ö§Ø§Ý§Ú§Ó§à§Ô§à §á§â§à§Ú§Ù§Ó§à§Õ§ã§ä§Ó§Ñ §ã §ã§Ú§ã§ä§Ö§Þ§à§Û §á§Ý§Ñ§ß§Ú§â§à§Ó§Ñ§ß§Ú§ñ §â§Ö§ã§å§â§ã§à§Ó §á§â§Ö§Õ§á§â§Ú§ñ§ä§Ú§ñ (ERP), §ã§Ò§Ñ§Ý§Ñ§ß§ã§Ú§â§à§Ó§Ñ§ß§ß§à§ã§ä§î §ä§Ö§Ü§å§ë§Ú§ç §â§Ö§ã§å§â§ã§à§Ó, §á§à§Ó§í§ê§Ö§ß§Ú§Ö §ï§æ§æ§Ö§Ü§ä§Ú§Ó§ß§à§ã§ä§Ú §á§â§à§Ú§Ù§Ó§à§Õ§ã§ä§Ó§Ö§ß§ß§à§Û §Þ§à§ë§ß§à§ã§ä§Ú.

SMT

and Reflow Soldering Line

Welding Production:

Assembly Production:

Calibration and Testing:

Aging and Testing:

Warehouse:

Shipping:

Power System Production:

QC Structure consist of IQC, IPQC, FQC, OQC process for the whole production:

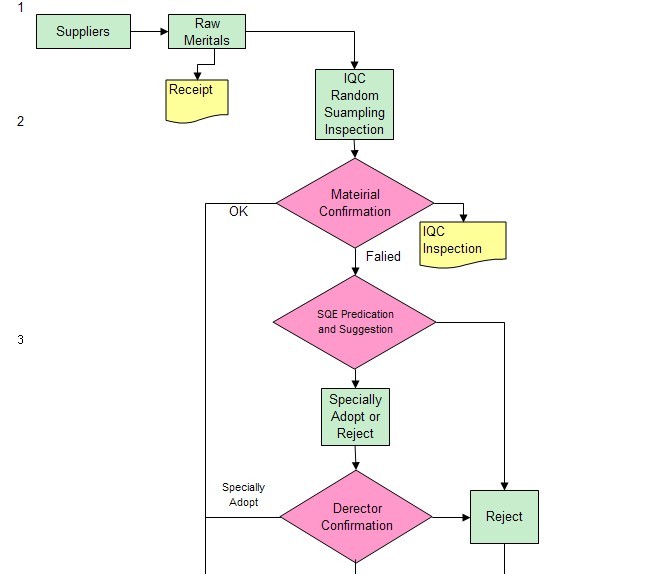

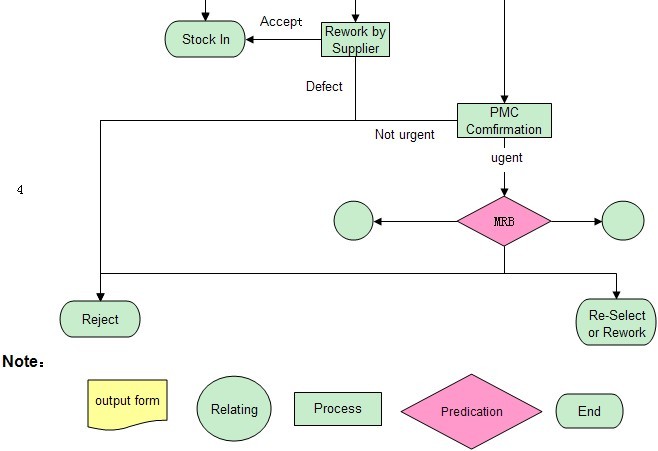

1. IQC

IQC is our first stage for QC process. We select the most reliable suppliers, most of them have been cooperating with us for over 2 years.

When we purchase raw materials and spare parts, our IQC member would make random inspection to the incoming materials according to " Incoming Materials Inspection Procedure ". If pass test, then could stock in. If failed, then reject. IQC could basically guarantee our reliable quality products on the original stage, we stress a lot on that.

IQC Process:

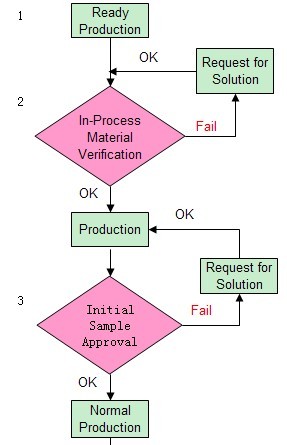

2. IPQC & FQC

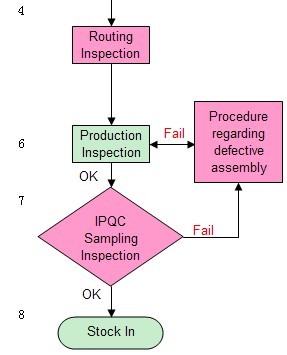

After the IQC for raw materials, there come the IPQC & FQC for Production and Assembly. It is the key stage for QC process.

First, make inspection for the in-process material, when pass test, proceed production. when fail test, notify production director to handle. production can only be proceeded after confirmation by IPQC.

Second, Initial Sample Approval. when pass test, proceed mass production. when fail test, notify production director to handle. mass production can only be proceeded after confirmation by IPQC.

Third, routing inspection every 2 hours, covers assembly, test, verification of operation and production documents.

Fourth, QC engineer make random sampling inspection every 2 hours.

Fifth, final-product stock in after FQC.

IPQC & FQC is the main part of QC process, also with the ISO9001 & ISO14001 certifying, all these would be the best backup for high quality products.

IPQC Process:

3. OQC

We would make final OQC inspection and testing before delivery, which we hold zero defect as permanent goal in our QC system.